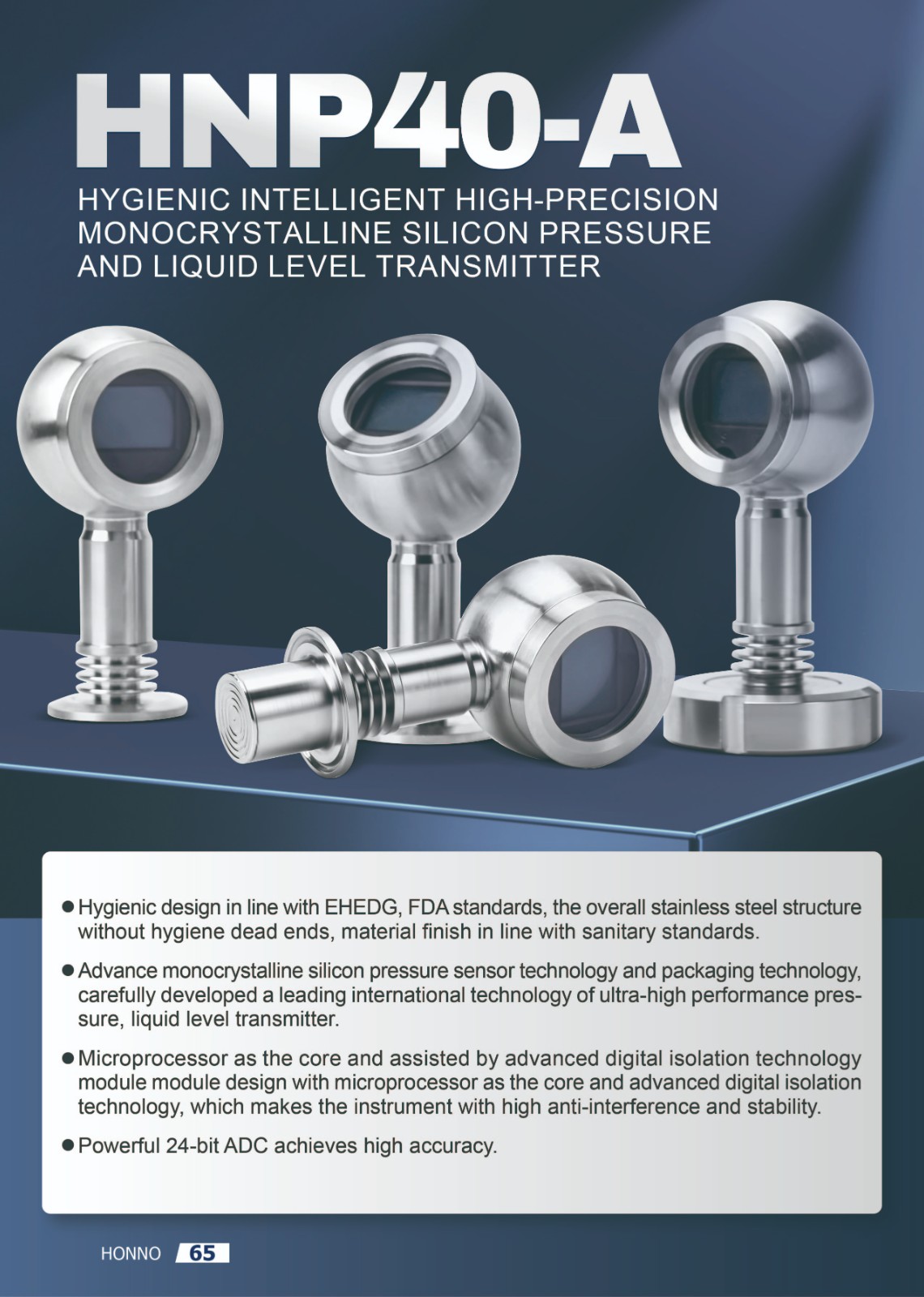

Hygienic pressure and level transmitters are high-performance transmitters developed by our company to cope with cleaning-in-place (CIP) and sterilization-in-place (SIP) in the pharmaceutical and food industries. Cleaning-in-Place (CIP) and Sterilization-in-Place (SIP) are the best methods available for cleaning process systems. They ensure safety and efficiency, prevent product contamination with toxic substances, and minimize process recontamination.

The use of high temperature steam sterilization (up to 150°C/302°F) for sanitary pressure and level transmitters is to ensure that food and drug products do not come into contact with toxic, hazardous, or contaminated substances through the transmitter. The materials, construction, and clean handling of the transmitter in direct contact with food and drugs need to be designed to meet EHEDG and FDA standards. Selected sealing rings, adhesives, conduction fluid shall not contain toxic and harmful components, the structure requires a clean surface, no dead ends, not easy to accumulate dirt residue, easy to rinse and sterilization.

The center sensing unit adopts high-precision monocrystalline silicon pressure sensor technology and encapsulation process, monocrystalline silicon pressure sensor is located at the top of the metal body, away from the media contact surface, to achieve mechanical isolation and thermal isolation, glass sintered sensor leads to achieve a high-strength electrical insulation with the metal substrate, to improve the flexibility of the electronic circuit can be protected from transient voltages and the ability to do so.

The temperature influence change is very small, the optimum can be controlled in the 0.05%/10K. In the circuit adopts the microprocessor as the core and auxiliary to the advanced digital isolation technology design, so that the instrument has a very high anti-interference and stability. Hart protocol can be used for communication, can be operated remotely through the Hart hand manipulator or computer with Hart software installed to complete the measurement information configuration, while using digital compensation technology, and through the built-in temperature sensor for temperature compensation of the transmitter to improve the measurement accuracy and reduce the temperature drift, with good long-term stability, reliability and other characteristics.

Contact: HongNuo

Phone: 13840589744

Tel: 86-13840589744

Email: Guiyang.bai@honno-auto. com

Add: Zhongguancun Innovation Center, No. 28 Huahai Road, Shenyang Economic and Technological Development Zone, Liaoning Province

We chat